How IoT is Revolutionizing Manufacturing

In recent years, the Internet of Things (IoT) has emerged as a game-changer in various industries, especially in manufacturing. IoT technologies have revolutionized the way products are designed, produced, and distributed, leading to increased efficiency and productivity in manufacturing processes.

Enhanced Data Collection and Analysis

One of the key benefits of IoT in manufacturing is the ability to collect real-time data from various systems and machines on the production floor. This data can then be analyzed to optimize processes, improve quality control, and reduce downtime. IoT sensors and devices can monitor everything from machine performance to environmental conditions, providing valuable insights for decision-making.

Smart Supply Chain Management

IoT technologies have also transformed supply chain management in manufacturing. By connecting different components of the supply chain through IoT devices, manufacturers can track and manage inventory, monitor shipments in real-time, and predict demand more accurately. This leads to smoother operations, reduced costs, and better customer satisfaction.

Predictive Maintenance

One of the most significant impacts of IoT in manufacturing is predictive maintenance. By leveraging machine learning algorithms and IoT sensors, manufacturers can now predict when a machine is likely to fail and take proactive measures to prevent downtime. This not only reduces maintenance costs but also increases the lifespan of equipment.

Automation and Robotics

IoT has enabled greater automation in manufacturing through the use of robotics and smart machines. These automated systems can communicate with each other in real-time, making production processes more efficient and flexible. IoT-powered robots can perform repetitive tasks with precision and accuracy, freeing up human workers to focus on more complex tasks.

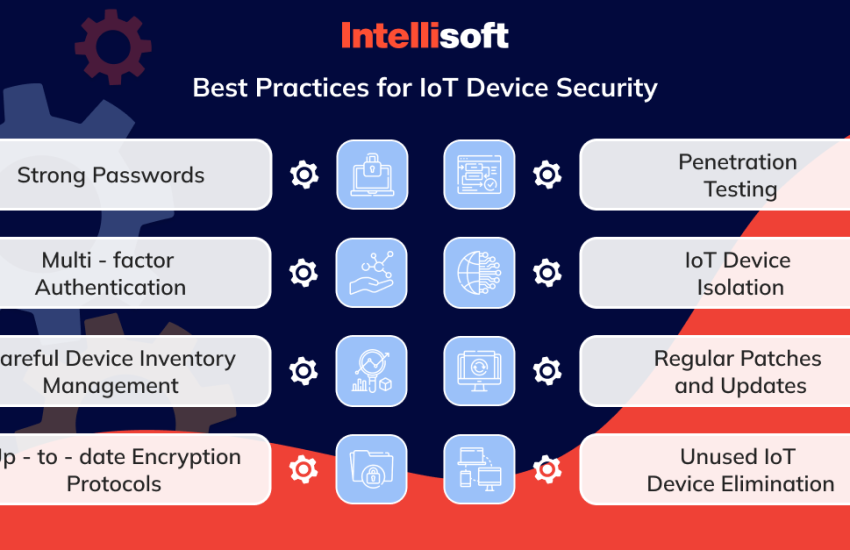

Improved Safety and Security

With the proliferation of connected devices in manufacturing, ensuring the safety and security of data and operations has become a top priority. IoT technologies enable manufacturers to monitor equipment and processes from a distance, detect safety hazards in real-time, and implement security measures to protect sensitive information. This not only enhances worker safety but also safeguards the integrity of the manufacturing process.

Challenges and Future Opportunities

While IoT has brought about significant advancements in manufacturing, there are still challenges to overcome, such as data privacy concerns, interoperability issues, and cybersecurity threats. However, with ongoing advancements in technology and increased investment in IoT solutions, the future of manufacturing looks bright. Manufacturers who embrace IoT will be better equipped to meet the demands of a rapidly evolving market and stay ahead of the competition.

Conclusion

In conclusion, IoT is revolutionizing the manufacturing industry by improving data collection and analysis, optimizing supply chain management, enabling predictive maintenance, increasing automation, and enhancing safety and security. As manufacturers continue to leverage IoT technologies, we can expect to see further advancements in productivity, efficiency, and innovation in the manufacturing sector.